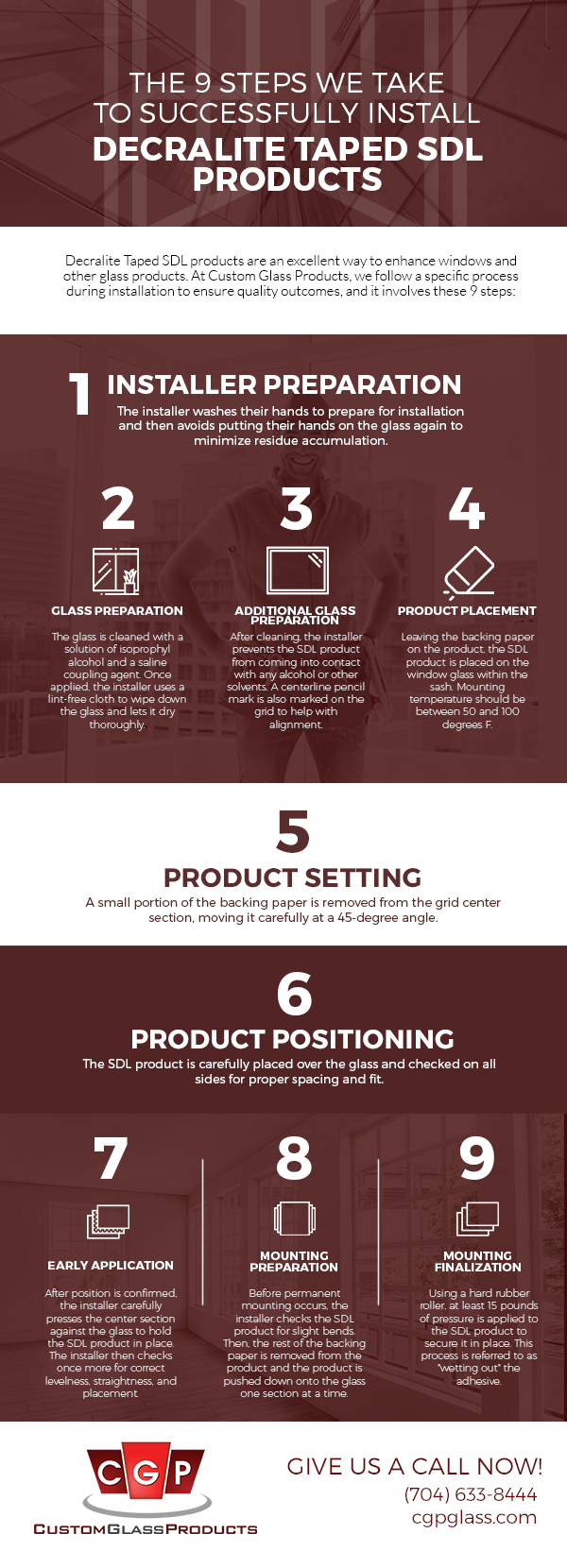

Preparing the Surface

To prepare for the installation process, the installer will start things off by washing their hands thoroughly. After they do this, they get the glass ready by cleaning it with a solution of saline and isopropyl alcohol using a lint-free wiping cloth. The glass is left to dry completely, and from this point on, the installer will avoid putting their hands directly on the glass to minimize residue.

Placing and Setting the Decralite® SDL Product

Once the surface of the glass has been cleaned, a centerline pencil mark will be added to the grid and grid point on the sash to help with alignment. Then, with the backer paper still on the Decralite® SDL product, the installer places the product on the window glass within the sash.

The installer looks for a good, dry fit, which means there is no stress on the SDL product after placement, there is enough space on either side of the sash, and the mounting temperature in the area is somewhere between 50 and 100 degrees Fahrenheit. The SDL product can then be set by peeling off the backer paper in small sections and rotating it at a 45-degree angle. After doing this, the installer will double check for levelness, straightness, and spacing before pressing in the center section.

Finishing Off the Process

After placing and setting the Decralite® SDL product, the installer gets ready for permanent mounting by checking for slight bends and the correct positioning. Finally, the installer can remove the backer paper and push it down onto the window glass a section at a time. Using a hard rubber roller, the installer will apply at least 15 pounds of pressure to every square inch during a process known as “wetting out” the adhesive.

The process for installing a Decralite® SDL product takes several steps, but when done properly, windows and glass can take on an entirely new and interesting look. if you have any questions about our installation process or any of the Decralite® products we use, call us today!